Nepal: Green Hydrogen Ecosystem 2040

Farewell to Fossil Fuel

Carbon dioxide (CO2) makes up the vast majority of greenhouse gas emissions from the sector, but smaller amounts of methane (CH4) and nitrous oxide (N2O) are also emitted. These gases are released during the combustion of fossil fuels, such as coal, oil, and natural gas, to produce electricity and other uses. Of the total emissions of greenhouse gas, about 28% of the emission originates from the transportation sector, whereas electricity production contributes 27% of emission followed by industries with 22%. Because of greater supply and cheaper prices, natural gas usage has surged, with an attendant 2.6 percent increase in carbon dioxide emissions for 2019.

In fact, rising natural gas use accounts for 60 percent of fossil emissions growth in recent years. However, the recent advancements in the sector of green hydrogen energy have given hope to farewell fossil fuels. Developments and researches for green hydrogen use in the transportation sector from fuel cell ships to cars and trucks, and planes, agriculture sector, and from industries to smart cities have raised the momentum on green hydrogen fuel. The massive impact of carbon dioxide and other harmful emissions from fossil fuels is causing the degradation of both the health and property but also the non-renewability of them is propelling Scientists, engineers, investors, and politicians to discuss and advance on the alternatives of fossil fuels.

Production

Waste Water to Hydrogen using Biogas Plant

Hydrogen is commonly accepted as one of the core renewable energy fuels we need. Modern wastewater treatment technology is a potential source of this fuel for the future. It is well established that methane or natural gas is produced by anaerobic digestion of the kind commonly found in water treatment operations. Biogas plants rely on anaerobic digestion, a fermentation process in which waste is digested by microbes to produce methane gas (biogas). The waste can be converted into biofertilizer and spread directly onto fields, or the biogas itself can be used interchangeably with natural gas as fuel. Like fossil-derived natural gas, this can be reformed to extract the hydrogen. Anaerobic treatment is seen as a proven key technology for recycling energy and wastewater nutrients since it transforms organic material into hydrogen and methane that provide electricity and heat and at the same time provides low levels of excess sludge. Biohydrogen has been developed and suggested as the ultimate transport fuel for vehicles and vessels due to its non-polluting nature and also allows the use of highly efficient fuel cells to turn chemical energy into electricity. In the last decade many innovations for processing biohydrogen have been proposed including bio-photolysis, photo fermentation, microbial fuel cells/electrolysis (MECs and MFCs), and dark fermentation, last seems to be the most pragmatic and feasible.

Hydrogen can be produced by splitting water using an electrolyzer, a process called electrolysis. Electrolyzers can vary in size from compact, appliance-sized equipment that is well suited for small-scale distributed hydrogen production to large-scale, central production facilities that may be directly connected to sustainable or other non-greenhouse-gas-emitting modes of electricity generation. Electrolyzers consist of an anode and a cathode separated by an electrolyte. Different electrolyzers work in slightly different ways, mostly due to the different forms of electrolyte content used. In a polymer electrolyte membrane (PEM) electrolyzer, the electrolyte is a solid specialty plastic material.

- Water reacts at the anode to form oxygen and positively charged hydrogen ions (protons).

- The electrons flow through an external circuit and the hydrogen ions selectively move across the PEM to the cathode.

- At the cathode, hydrogen ions combine with electrons from the external circuit to form hydrogen gas.

- Alkaline Electrolyzers: Alkaline electrolyzers operate with hydrogen being generated on the cathode side via the transport of hydroxide ions (OH-) through the electrolyte from the cathode to the anode. Electrolyzers using a sodium or potassium hydroxide liquid alkaline solution as the electrolyte have been commercially available for many years. Recent approaches are showing promises on the lab scale with solid alkaline exchange membranes.

- Solid Oxide Electrolyzers: Hydrogen is generated in a slightly different way by solid oxide electrolyzers that use a solid ceramic material as the electrolyte that selectively conducts negatively charged oxygen ions (O2-) at elevated temperatures.

i) Water at the cathode combines with external circuit electrons to form hydrogen gas and negatively charged oxygen ions.

ii)The oxygen ions pass through the solid ceramic membrane and react at the anode to form oxygen gas and generate electrons for the external circuit.

Green Hydrogen from Hydropower

Countries with high hydropower potential also have high hydrogen potential as the water can be electrolyzed to form hydrogen using the electricity produced by hydropower. Hydrogen produced from renewable energy sources is called Green Hydrogen which seems to be a promising future in the field of clean energy. Other than just producing hydrogen using hydro-electricity, it can also be regarded as a way to store electricity as hydrogen can later be used to produce electricity again.

Countries like Switzerland, Norway, Netherlands, and Norway are practicing this technique of producing hydrogen using hydro-electricity and in the same way, Nepal also holds significant potential, and for the same reason, Green Hydrogen Laboratory at Kathmandu University has been established. This technique can be seen as one of the possibilities for increasing the efficiency of hydropower plants by conversion of water to hydrogen through electrolysis by using the excess energy or wasted energy not yet utilized, and then conversion of hydrogen to electricity via a gas turbine or fuel cells. The electricity produced in the off-peak or no-demand time, or at the time of huge river flows in the spring can be stored in the form of hydrogen, and later, when the peak energy is needed, the hydrogen converted to electricity.

Green Hydrogen from Solar Power Plant and Wind Energy

Similar to the production of hydrogen from hydropower, in the places where hydropower potential is low, such as the Terai regions of Nepal and Upper Himalayan regions, solar power plants or wind turbines can substitute the hydropower plants for producing hydrogen by electrolysis of water using solar energy and wind energy.

Storage and Distribution

Cross-Border Hydrogen Export

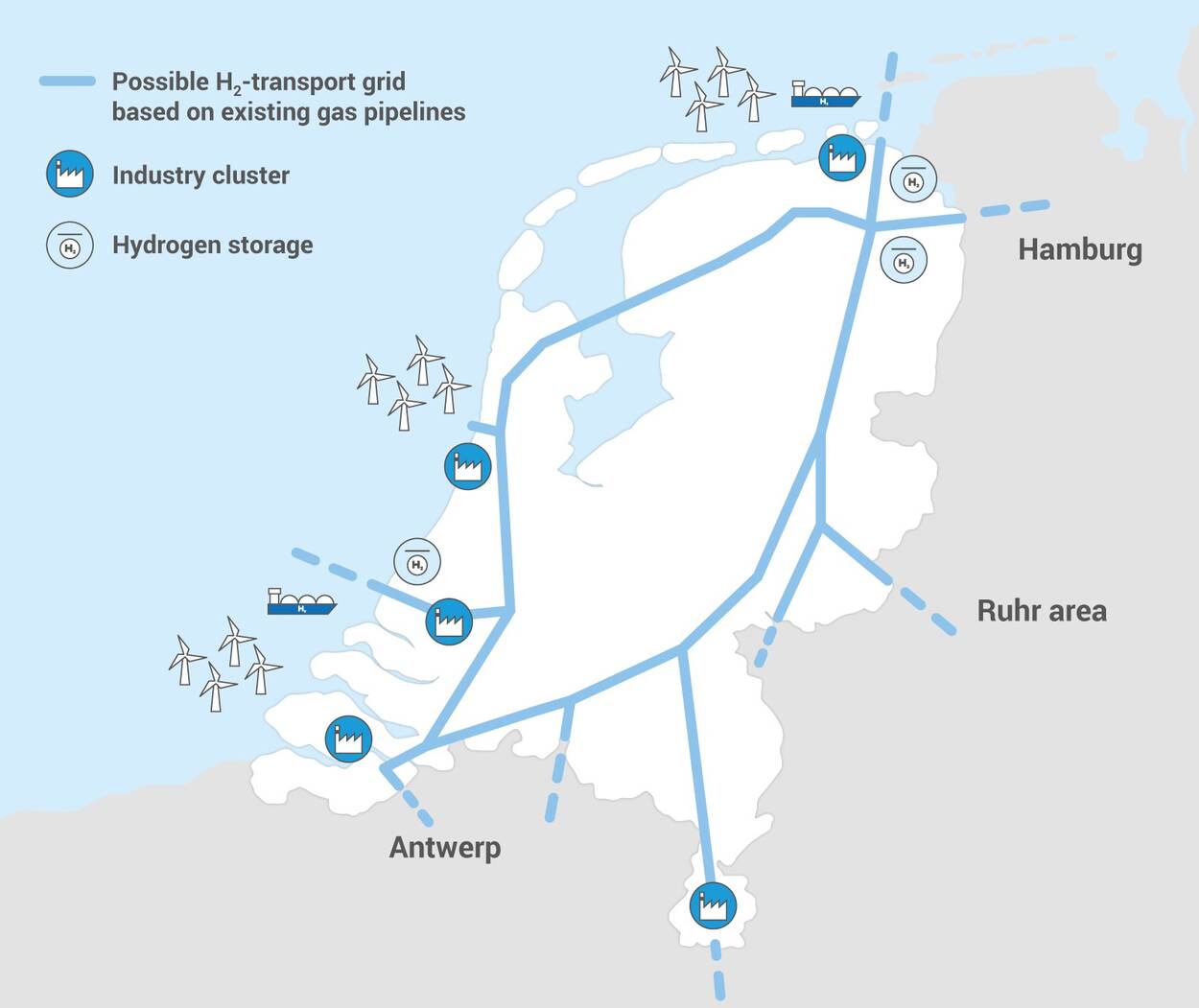

Hydrogen is one of the highly used gas as it has a wide range of use from fertilizer production to fuel-cell vehicles. Therefore, cross-border export of hydrogen is a promising future in the field of the green energy market. Gaseous hydrogen can be transported through pipelines much the way natural gas is today. Approximately 1,600 miles of hydrogen pipelines are currently operating in the United States. And hydrogen transportation using ship cargos can also be taken as an alternative to pipelines which seems less feasible economically in fact a pipeline network would be the best option for the comprehensive and largescale use of hydrogen as an energy source. However, pipelines require high levels of initial investment, which may pay off, but only with correspondingly large volumes of hydrogen. Nevertheless, one possibility for developing pipeline networks for hydrogen distribution is local or regional networks, known as micro-networks. These could subsequently be combined into transregional networks.

Hydrogen Tube Trailers/Tankers

Tube trailers or tankers are used to transport gaseous hydrogen and liquified hydrogen. Usually, hydrogen is transported as a liquid in insulated, cryogenic tanker trucks, and also in bulk by rails with double walls, multi-layer insulation, and sunlight reflectors.

Typically, hydrogen is transported in tube trailers in the UK. A typical trailer would be filled to 228 bars and would carry around 300 kg of hydrogen. There are now available on the market, high capacity 300 bar trailers, which could carry 600 kg at 228 bar and 900 kg at 300 bars. There are also 500 bar trailers in development.

Hydrogen Fueling Station

Analogous to traditional gas fueling stations hydrogen fueling station serves as a storage/ filling station for hydrogen though they have more complex architecture. Hydrogen filling stations consist of additional devices such as a compressor unit which is used to compress the gas to a required pressure, and devices for the delivery of the gas. Some stations even contain production facilities in-case-of on-site refueling station. Furthermore, the potential risk of possible ignition of hydrogen at the station or in the vehicle during refueling increments additional rise of risk, which must be well-evaluated. According to the mode of delivery, there are two types of stations: i) off-site hydrogen recharging station, and ii) on-site recharging station. In the case of an off-site refueling station, hydrogen is supplied via pipelines, tube trailers etc. whereas in the case of on-site refueling station hydrogen is produced by extracting natural gas, electrolysis etc. at the recharging station.

As of 2020, there are 178 publicly available hydrogen stations of which 114 are situated in Japan alone. Similarly, Europe has more than 180 stations and the US has seen 44 stations as of 2020.

Electricity Grid

Since, storing hydrogen produced from renewable energy sources is a way of storing energy, the electricity produced from the stored hydrogen gas can be supplied to the existing electricity grid fulfilling the peak-hour electricity demand. Other than transporting hydrogen gas through different medium supplying hydrogen energy to the electricity grid is one of the ways to harness green hydrogen energy. The beauty of this concept is that it is based on an already existing infrastructure.

Electricity Grid to "End-Use"

As green hydrogen can serve as a way of storing energy produced from renewable energy sources, electricity later extracted from hydrogen can be used for electric vehicles and industrial and household uses transported through electricity grids.

Smart Cities

Supplying Green Energy to Apartment, Hotels and Malls

Typical hotels and apartments consume energy more than 10 times the normal households consume. Hotels all around the world are making efforts to be more eco-friendly. From using less water to building with sustainable materials, there seem to be endless options for properties to minimize their environmental impact.

Similarly, using green energy at shopping malls can transform the energy grid and enable it to become safer, cleaner, and more flexible reducing energy costs and providing a backup power source. Therefore, similar to the tourism sector and sports sector hydrogen energy can create sustainable systems in apartments, shopping malls, and hotels.

Green Hydrogen Energy for Tourism sector

Economically, socially, and environmentally sustainable fast-growing tourism sector can be achieved only by using recyclable or renewable technologies, protecting the environment, respecting local cultures, improving local communities, involving businesses, staffs, and tourists in sustainable practices, minimizing energy usage and pollution and conserving cultural and natural assets. About 5% to 12% of greenhouse gas emission is directly connected to the tourism sector, whereas it also holds significant potential for the world economy. As many eco-conscious travelers are keeping tabs on their CO2 flight emissions by purchasing carbon offsets, the sky is the limit for travelers who want to explore the world responsibly. Thus, Green hydrogen energy systems can play a significant role in sustainable and eco-friendly tourism.

Harvesting Green Hydrogen in Stadiums

Stadiums consumes as much energy in 90 minutes as a dozen of homes consume for an entire year. Floodlighting, scoreboards, advertising screens, heating and cooling systems, powerful satellite transmitters, and countless HD cameras consume a vast magnitude of energy that they leave a significant amount of carbon footprint. Therefore, powering stadiums with green hydrogen energy can create a sustainable energy foundation in the field of other sports sectors too.

Universities and Green Hydrogen

For the transition towards green hydrogen energy Universities play a central and crucial role through continuous research and innovations carrying different development activities. Universities are the think tanks of the society and source of innovations for the smart cities, and through local and global collaboration can develop ideas and methods for the transition towards green hydrogen energy offering courses and research projects in green energy.

Smart Homes

With the development of newer and efficient technologies automation in homes is increasing shifting them to become a smart home. But green smart homes are what the eco-friendly homes featured with the latest technology. These homes meet the needs and want of their occupant without harming the environment. Daylight manage Lighting System, Water Efficient Fittings,

Rainwater Harvesting, Occupancy Sensors are some of the features of the smart home all which needs electricity. Such electricity can be provided from hydrogen produced energy through electricity grids transforming smart homes into green smart homes.

Industrial Revolution

Agriculture

Nepal is an agricultural country. Its 66 percent population is directly engaged in farming. Farming is subsistent in nature and crop is mostly integrated with livestock. Nepal is richly endowed with agro-biodiversity. In fact, the economy of the country is dominated by agriculture. In trying to increase agricultural production and diversify the agricultural base, the government focused on irrigation, the use of fertilizers and insecticides, the introduction of new implements and new seeds of high-yield varieties, and the provision of credit.

However, the lack of resources and fertilizers, which are exported from third countries, farmers struggle each year with lower harvesting of corps impacting the national economy. In this case scenario, green hydrogen production in the home country can play a major role in agriculture. Not only hydrogen can be used to produce fertilizers but can also be used as Hydrogen water treatment to irrigate crops promoting plant growth. In plants, hydrogen gas enhances tolerance to several abiotic stresses, including salinity and heavy metals which could be beneficial in the entire agricultural system.

Food Processing

In the food industry, hydrogen is used for fat hardening where hydrogen turns unsaturated fats into saturated oils and fats. Vegetable oils such as margarine and butter are manufactured employing hydrogen in a process called Hydrogenation. Factories use blue hydrogen, which is extracted using natural gas, however, green hydrogens can be used for a cleaner way of hydrogen use in food industries. Furthermore, with the rise of the concept in green hydrogen technology, many food operations have adopted the use of fuel cell technology, with thousands of fuel cells now supplying power to processing facilities and bakeries, helping to move stock in warehouses and providing reliable energy to supermarkets.

Cement Industries

The cement industry contributes about 5% to global anthropogenic CO2 emissions, making the cement industry an important sector for CO2-emission mitigation strategies. CO2 is emitted from the calcination process of limestone, from the combustion of fuels in the kiln, as well as from power generation. In such a case, a large proportion of the green hydrogen can be combined with carbon dioxide captured from the cement plant to produce synthetic methanol, which would then be refined into carbon-neutral synthetic kerosene. Besides, hydrogen and oxygen could be burned instead, replacing the fossil fuels entirely in heating chambers.

Special Economic Zone

Special economic zones can provide a strategic and competitive platform for the development and production of green hydrogen systems. In addition to that as SEZs also attracts and facilitates foreign investments integrating local firms into global chains, they can be established as a hub for the development and export of green hydrogen fuel and technologies.

Chemical/ Fertilizers Plant

Hydrogen is a major ingredient for many organic and non-organic chemicals, combining which fertilizers are produced. About 55 % of the hydrogen, a fundamental building block for the manufacture of ammonia, produced around the world is used for ammonia synthesis, 25 % in refineries- where hydrogen is used for the processing of intermediate oil products, and about 10 % for methanol production.

From making types of polymers to desulfurization of hydrocarbons to produce sulfur-free fuels, a significant amount of hydrogen is used in chemical and fertilizer industries. Thus, supplying this magnitude of green hydrogen can significantly reduce the global carbon footprint. Besides, chemical plants are also important for the production of green hydrogen as they can develop and lead the water electrolysis systems using renewable energies.

From making types of polymers to desulfurization of hydrocarbons to produce sulfur-free fuels, a significant amount of hydrogen is used in chemical and fertilizer industries. Thus, supplying this magnitude of green hydrogen can significantly reduce the global carbon footprint. Besides, chemical plants are also important for the production of green hydrogen as they can develop and lead the water electrolysis systems using renewable energies.

Mining Industry

With hydrogen gaining momentum as an alternative to fossil fuel, mine industries may ultimately devote their renewable energy resources toward hydrogen production, which could become a sustainable revenue center. Mines can be located in areas of high solar or wind intensity and may even become surplus producers, continuing to generate hydrogen well after the mine’s resources have been exhausted and the mine has closed. About 4 to 7 percent of global greenhouse-gas and carbon dioxide-incurred through mining operations and power consumption is generated from mining industries and 3 to 6 percent of fugitive-methane emission is caused from coal-mining all of which can be suppressed by producing and using green hydrogen at mining operations.

Hydrogen Fueled Transportation

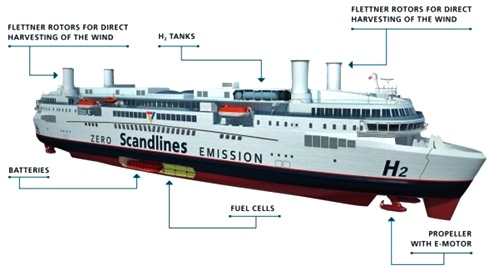

Fuel Cell Ships and Boats

Ships already emit 3 percent of all greenhouse gases, and if the sector proceeds on a business-as-usual course, emissions are expected to increase by up to 50 percent by 2050. It takes a lot of energy to haul a ship across the sea, and as world trade increases, there is a growing number of ships to haul. Any of this energy may be lowered to minimize pollution by ships using more compact designs, adding wind harnessing systems, traveling a little slower to save power or even bringing less material. Ultimately, though, if shipping is going to decarbonize entirely, and if the world is to remain within reasonable temperature limits, it would have to find a fossil fuel substitute, for which Green Hydrogen is the major candidate. Once the hydrogen is produced, there are several ways it can be used to power ships.

It can be burnt in an internal combustion engine or can be used in fuel cells and another way currently being researched is driving a turbine generating electricity using steam generated by burning hydrogen with pure oxygen. But the real difficulty of using it in long-distance shipping is how tricky it is to store it. Hydrogen cannot simply substitute bunker fuel in the existing method. In order to store it on board a ship as a liquid, it needs to be frozen at cryogenic temperatures of-253C, and it also takes up a lot of space-about eight times more than the amount of marine gas oil used to supply the same amount of energy.

Fuel cell boats use hydrogen as the source of power as similar to other hydrogen technology vehicles. However, one more advantage FC boats have got is the concept of producing hydrogen onboard using seawater utilizing boats.` surface area covered with solar panels.

Hydrogen Bus

With the raised concerns in sustainable development high hopes for hydrogen is increasing to get sustainable transport on track. Green hydrogen has long been viewed as critical to getting mass transportation on the road to zero emissions by a host bodies to tackle air pollution. Many countries like Denmark, UK, Japan, Norway are preparing for the deployment of hydrogen buses on the road.

Fuel cell electric buses offer a one-to-one replacement for diesel and CNG buses, with no compromise in service. In addition, quick refueling of hydrogen provides less downtime for buses giving higher utilization.

Hydtrails

All forms of rail vehicles, large or small, which use on-board hydrogen fuel as a source of energy to power the traction motors, or the auxiliaries, or both are called Hydrails. Hydrail vehicles use the chemical energy of hydrogen for propulsion, either by burning hydrogen in a hydrogen internal combustion engine or by reacting hydrogen with oxygen in a fuel cell to run electric motors.

Widespread use of hydrogen for fueling rail transportation is a basic element of the proposed hydrogen economy. Hydrail vehicles are usually hybrid vehicles with renewable energy storage, such as batteries or supercapacitors, for regenerative braking, improving efficiency, and lowering the amount of hydrogen storage required.

Add Your Heading Text Here

Similar to Hydrogen Buses and Hydrails, Fuel cell cars and bikes work on the same principle and technology-in fact they can be referred to as Hydrogen cars and Bikes.

Fuel cell E-Bikes can have a 60 plus miles range with a refueling time of 2 minutes whereas fuel cell cars take less than three minutes to refuel with a total range of up to 312 miles. In principle, a hydrogen fuel cell functions as a battery, producing electricity, which can run an electric motor. Instead of requiring recharging, however, the fuel cell can be refilled with hydrogen.

Hub of Aviation Fuel

Green Hydrogen has another possibility for being used as aviation fuel. Recent developments and researches from Companies like Airbus and Boeing, and other research institutes for hydrogen-fueled planes, vector for the Green hydrogen aviation fuel seem promising.

Hydrogen can either be burned in a jet engine, or other kinds of the internal combustion engine, or can be used to power a fuel cell to generate electricity to power a propeller. Unlike most aircraft, which use wings for storing fuel, hydrogen aircraft are usually designed with the hydrogen fuel tanks carried inside the fuselage. Green hydrogen can be stored in the airports or can be produced on-site making airports hub for aviation fuel becoming a strategic supplier of hydrogen and hydrogen storage.

Hydrogen Trucks

Growing momentum on FCEVs has also centered the development of hydrogen trucks. Nikola has developed an FCEV truck that can run 1100 km just in one fill of hydrogen. Similarly, Hyundai, Toyota, and Hyzon motors have also developed and delivering fuel cell trucks.

A significant number of trucks are used worldwide on a daily basis that emits tons of carbons; therefore, hydrogen trucks could be their ideal replacement.